In industries that rely on fuel-burning systems, understanding and optimizing combustion processes is vital. Combustion analysis plays a key role in enhancing efficiency, reducing environmental impact, and ensuring system safety. Whether it’s for residential furnaces or industrial boilers, the importance of combustion analysis cannot be overstated. Here are five compelling reasons why combustion analysis is essential.

1. Maximizing Combustion Efficiency

One of the primary reasons for conducting combustion efficiency testing is to maximize the energy output from fuel. By analyzing the combustion process, technicians can identify inefficiencies and adjust the fuel-air ratio to achieve optimal performance.

Optimizing Fuel-Air Ratio

The fuel-air ratio is critical for achieving efficient combustion. Too much air can cool the combustion process and waste energy, while too little air can lead to incomplete combustion and carbon monoxide production. Combustion analysis ensures the proper balance is maintained.

Benefits of Increased Efficiency

- Lower fuel costs

- Reduced wear and tear on equipment

- Increased lifespan of combustion systems

If you’re experiencing heating issues, our guide on furnace is not blowing hot air provides insights into diagnosing and resolving common problems.

2. Ensuring System Safety

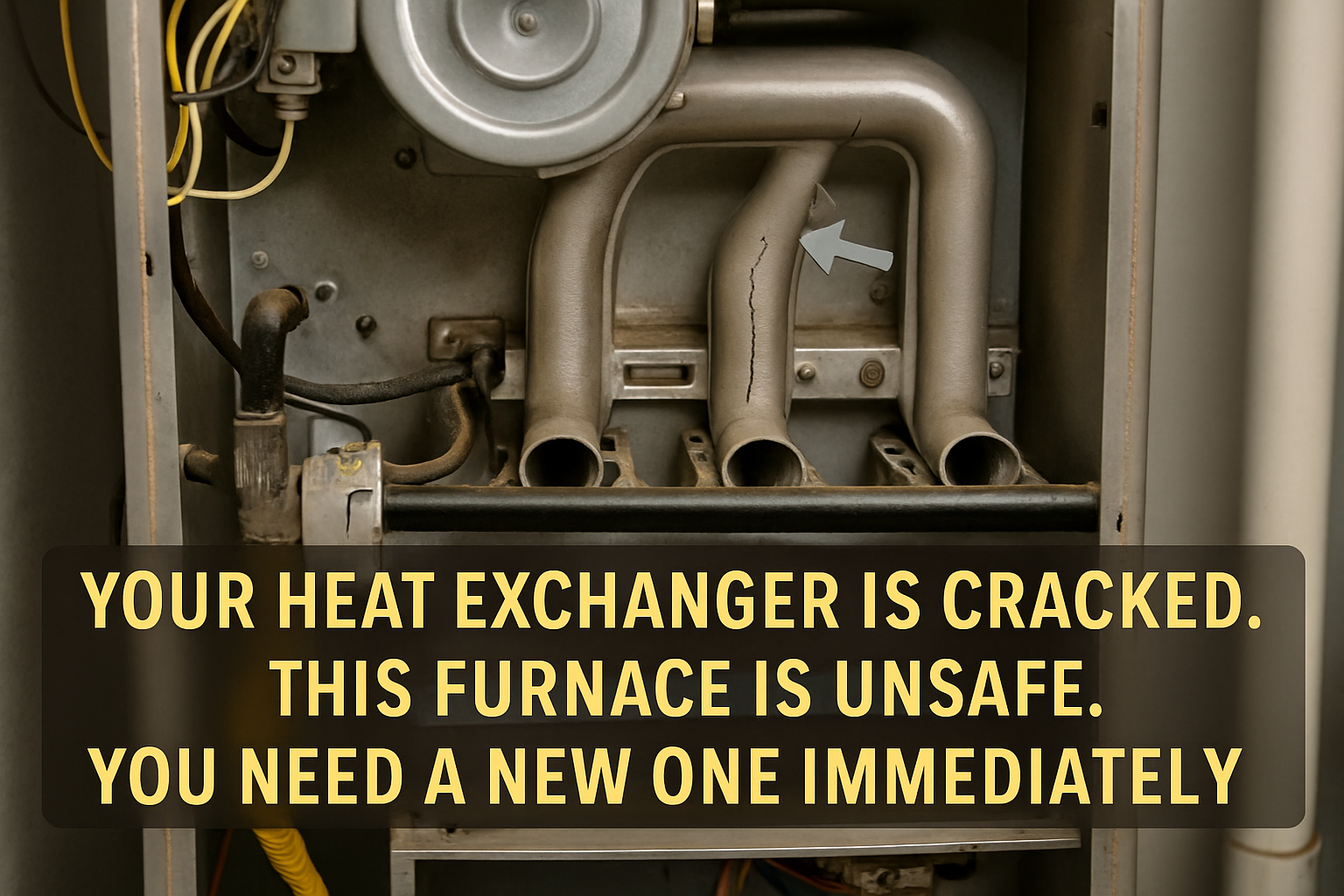

Safety is paramount in any system involving combustion. Faulty combustion processes can produce hazardous gases like carbon monoxide, which poses significant risks to human health.

Monitoring Combustion Performance

By monitoring combustion performance, technicians can detect irregularities such as incomplete combustion or excessive heat production. This proactive approach helps prevent dangerous conditions and ensures that safety standards are met.

Preventative Maintenance

Regular combustion diagnostics and maintenance not only keep systems safe but also avoid costly repairs. For tips on maintaining key components, check out our article on cleaning a furnace flame sensor.

3. Reducing Environmental Impact

In today’s environmentally conscious world, reducing emissions is a critical aspect of operating fuel-burning systems. Combustion analysis provides a pathway to achieve this goal.

Reducing Emissions Through Combustion Analysis

Incomplete combustion often results in the release of harmful pollutants, including carbon monoxide and nitrogen oxides. By optimizing combustion processes, emissions are minimized, contributing to cleaner air and compliance with environmental regulations.

Supporting Sustainability Goals

Industries that prioritize the environmental impact of combustion not only meet regulatory requirements but also demonstrate their commitment to sustainability, enhancing their reputation among customers and stakeholders.

4. Saving Energy and Reducing Costs

Energy efficiency directly correlates with cost savings. Through energy savings through combustion analysis, businesses can lower operational costs while maintaining effective performance.

Identifying Energy Wastage

Combustion analysis identifies areas where energy is being wasted, such as excessive heat loss or improper fuel use. Adjustments can then be made to improve efficiency.

Long-Term Savings

The cost of regular combustion testing is outweighed by the long-term savings achieved through reduced fuel consumption and fewer equipment failures. For additional tips on keeping systems running efficiently, check our annual furnace check-up services.

5. Enhancing System Performance

Why is combustion analysis important for fuel-burning systems?

Combustion analysis is essential because it helps maximize efficiency, ensure system safety, reduce environmental impact, save energy, and enhance overall system performance.

How does optimizing the fuel-air ratio improve combustion efficiency?

Optimizing the fuel-air ratio ensures the right balance of air and fuel, which maximizes energy output, minimizes waste, and prevents incomplete combustion or excessive heat production.

What safety benefits does combustion analysis provide?

Combustion analysis helps detect irregularities such as incomplete combustion or hazardous gases like carbon monoxide, preventing dangerous conditions and ensuring safety standards are maintained.

In what ways does combustion analysis contribute to environmental sustainability?

It reduces emissions of harmful pollutants like carbon monoxide and nitrogen oxides by optimizing combustion, supporting sustainability goals, and helping comply with environmental regulations.

How can combustion analysis lead to cost savings for businesses?

It identifies areas of energy wastage, allowing adjustments to improve efficiency, which reduces fuel consumption and prolongs equipment lifespan, leading to long-term savings.

Optimizing combustion systems leads to smoother operation, increased reliability, and better overall performance.

Benefits of Combustion Diagnostics

Through combustion diagnostics, technicians gain valuable insights into system performance, allowing them to fine-tune operations and prevent downtime.

Application Across Industries

Whether it’s a residential furnace or an industrial boiler, combustion analysis ensures that systems operate at peak performance. For homeowners, our furnace repair services page guides addressing common issues and ensuring effective heating.

Tools and Techniques for Combustion Analysis

Analyzers and Sensors

Combustion analysis relies on advanced tools like gas analyzers and sensors to measure levels of oxygen, carbon monoxide, and other gases. These measurements inform necessary adjustments to optimize combustion.

Data Interpretation

Skilled technicians interpret the data collected during analysis, identifying trends and making precise modifications to improve system performance.

Conclusion

The importance of combustion analysis cannot be overstated. From maximizing efficiency and ensuring safety to reducing emissions and saving energy, this process is crucial for maintaining effective and sustainable combustion systems. Whether you’re troubleshooting a furnace or optimizing an industrial boiler, understanding the role of combustion analysis is the first step toward achieving superior performance.

Written By: George

George

George

George