Commercial refrigeration maintenance involves a proactive approach to ensuring refrigeration systems in businesses like restaurants, grocery stores, and warehouses operate efficiently, reliably, and safely. This essential practice preserves perishable goods, minimizes operational disruptions, and maximizes energy efficiency. By following a commercial refrigeration maintenance checklist, businesses can avoid costly repairs, extend equipment lifespan, and maintain optimal performance.

4 Advantages of Commercial Refrigeration Maintenance

1. Enhanced Efficiency

Regular maintenance ensures components like condensers and evaporators are clean and functioning optimally, reducing energy consumption and lowering utility bills.

2. Prolonged Equipment Lifespan

By addressing minor issues early, businesses can prevent significant damage and extend the operational life of their refrigeration systems.

3. Minimized Downtime

Preventative care reduces the likelihood of unexpected breakdowns, ensuring that operations run smoothly without costly interruptions.

4. Improved Food Safety

Consistent temperature and humidity levels are critical for preserving the quality and safety of perishable items, preventing spoilage, and reducing waste.

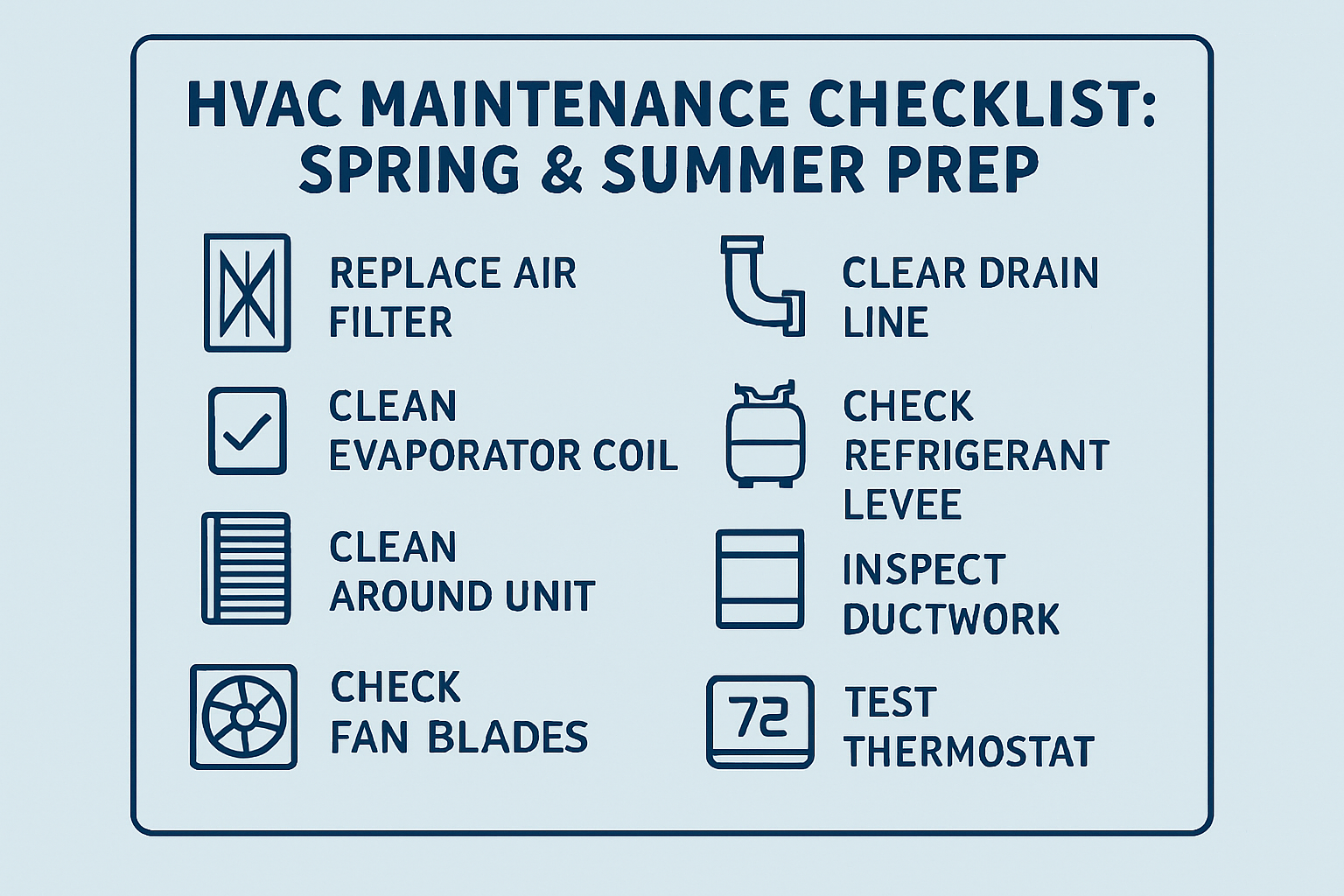

Commercial Refrigeration Maintenance Checklist

A thorough maintenance routine includes the following tasks:

1. Establish a Maintenance Schedule

- Perform maintenance at least twice a year, or more frequently in high-demand environments.

- Adhere to manufacturer-recommended intervals for inspections and servicing.

2. Inspect Door Seals and Gaskets

- Check for wear, damage, or gaps.

- Replace worn or damaged seals to prevent cold air leakage.

3. Clean Condenser and Evaporator Coils

- Remove dust, debris, and grease buildup with a soft brush or vacuum.

- Prevent airflow blockages that can hinder cooling efficiency.

4. Monitor Refrigerant Levels

- Ensure refrigerant levels are adequate and check for leaks.

- Schedule professional inspections for refrigerant-related issues.

5. Inspect and Replace Air Filters

- Regularly inspect and replace filters to maintain airflow and indoor air quality.

6. Calibrate Thermostats

- Check thermostat accuracy and adjust settings to maintain desired temperatures.

7. Monitor Temperature and Humidity Levels

- Install monitoring devices for consistent tracking.

- Take corrective action when deviations occur.

8. Inspect Drain Lines and Clean Drain Pans

- Prevent clogs and water buildup by regularly cleaning drain lines and pans.

9. Check Fan Motors and Blades

- Inspect for wear or damage.

- Clean blades and lubricate motors to ensure smooth operation.

10. Schedule Professional Servicing

- Conduct periodic professional inspections for in-depth diagnostics and preventative care.

Refrigeration Preventative Maintenance: Why It Matters

Preventative maintenance is essential for avoiding costly repairs and downtime. It ensures refrigeration systems remain energy-efficient, safe, and reliable by addressing issues before they escalate. Key aspects of refrigeration preventative maintenance include:

- Cleaning critical components like coils and filters.

- Monitoring refrigerant levels and system performance.

- Ensuring proper drainage to prevent mold or water damage.

Maintenance Frequency for Different Equipment

Walk-In Coolers

- Monthly: Inspect seals and clean coils.

- Quarterly: Perform a comprehensive system cleaning.

Display Cases

- Weekly: Clean surfaces and monitor performance.

- Annually: Schedule professional servicing.

Ice Machines

- Every Six Months: Sanitize and inspect water filters.

Tip: Refer to the manufacturer’s guidelines to tailor maintenance schedules for your specific equipment.

Optimal Temperature Ranges for Commercial Refrigeration

Reach-In Refrigerators

Similar to walk-in coolers, reach-in refrigerators should maintain a temperature between 35°F (1.7°C) and 38°F (3.3°C). Consistency is key, so it’s essential to monitor and ensure that the temperature remains uniform throughout the unit. Variations in temperature can occur due to factors such as frequent opening and closing of doors or improper stocking. Proper temperature management in reach-in refrigerators is crucial for extending the shelf life of refrigerated goods and minimizing food waste.

Walk-In Coolers

For most perishable goods stored in walk-in coolers, the ideal temperature range is between 35°F (1.7°C) and 38°F (3.3°C). This range strikes a balance between keeping food safe without risking freezing. Maintaining temperatures within this range helps preserve the freshness and quality of perishable items such as fruits, vegetables, dairy products, and beverages.

Commercial Freezers

To safely store frozen goods and prevent the growth of bacteria, commercial freezers should operate at 0°F (-18°C) or below. This temperature range ensures that food remains safely frozen, preserving its quality, texture, and safety over an extended period. Maintaining proper freezing temperatures is essential for storing a wide range of frozen products, including meats, seafood, poultry, and prepared meals.

How Professional Maintenance Benefits Businesses

1. Expert Diagnostics

Professionals can detect subtle issues that may not be apparent to untrained personnel, preventing major problems.

2. Compliance and Safety

Regular servicing ensures adherence to health and safety regulations, crucial for food businesses.

3. Cost Savings

At Four Elements Service, we specialize in commercial HVAC, commercial refrigeration, walk-in coolers and freezers, and commercial ice maker services. Our experienced technicians provide comprehensive maintenance solutions tailored to your business needs, ensuring your systems run efficiently and reliably.

Is Commercial Refrigeration Maintenance Worth It?

Absolutely. The investment in commercial refrigeration maintenance pays off through energy savings, operational reliability, and peace of mind. By following a regular maintenance routine and scheduling professional inspections, businesses can ensure their refrigeration systems operate at peak performance year-round.

For a reliable, efficient, and long-lasting refrigeration system, proactive maintenance is not just an option—it’s a necessity.

What are the main benefits of regular commercial refrigeration maintenance?

Regular commercial refrigeration maintenance enhances efficiency, prolongs equipment lifespan, minimizes downtime, and improves food safety by ensuring consistent temperature and humidity levels.

What tasks are included in a commercial refrigeration maintenance checklist?

A maintenance checklist includes establishing a schedule, inspecting door seals, cleaning coils, monitoring refrigerant levels, inspecting filters, calibrating thermostats, monitoring temperature and humidity, inspecting drain lines, checking fan motors, and scheduling professional servicing.

How often should different types of commercial refrigeration equipment be maintained?

Walk-in coolers should be inspected monthly and cleaned quarterly, display cases should be cleaned weekly and serviced annually, and ice machines should be sanitized and inspected every six months.

What are the optimal temperature ranges for various types of commercial refrigeration?

Reach-in refrigerators should stay between 35°F and 38°F, walk-in coolers also aim for 35°F to 38°F, and commercial freezers should operate at 0°F or below.

Why is professional maintenance important for commercial refrigeration systems?

Professional maintenance provides expert diagnostics, ensures compliance with safety regulations, and results in cost savings by preventing major issues and maintaining efficient system operation.